We perform the fundamental Tesla body shop welding repairs in Lucan , Ontario as well as in your shop welding repairs on Tesla body within mobile aluminum welding repair service. The Tesla aluminum body responds rather unexpectedly to impact due to minor accidents with multiple cracks on surfaces directly impacted. And what is more important, this impact creates material cracks to aluminum brackets holding the outside body panels of Tesla.

You can contact us and send multiple images of your damaged Tesla body. You can also text us on the phone number provided there and you can send the video on this number. After we do an excellent job, please leave the 5 stars review of our service.

The Tesla body shops are rather expensive for Tesla loving drivers. Tesla owners who got into minor accidents pay very substantial amount for repairs of their Tesla’s body work. Comparing to the same repairs on ordinary cars the repair of aluminum body of Tesla could be 3 times or even 4 times more expensive. But on the other side Tesla body should not rust many drivers will say.

Working on Tesla body is a skill that is slightly different than body work on normal cars since Tesla has aluminum panels and aluminum supporting brackets. These panels as in any car could be movable or fixed. The Tesla body shop technician can adjust position of movable body panel but this technician is not able to adjust the fixed panel position. The welded fixed panels are non movable.

By changing the position of multiple moveable panels the Tesla technician is able to remove or minimize the rather large A or V gaps between the panels that could range from 2 mm or 3mm to 7mm or even 9 mm. In this way the technician is able to remove typical Tesla body problems. This operation requires skill experience and labour time. Unfortunately, after the minor thunder bender this option is not possible since all brackets holding the movable panels are cracked. And, the panels themselves are cracked too.

It is true that Tesla body work is rather costly but there is the reason for it. First, the aluminum body panels cost more than traditional mild steel panels and for the obvious reasons. Secondly, during the minor thunder bender these panels crack a lot since they are made from aluminum. As the mild steel body panels bend, the aluminum panels crack under the impact. Third, the brackets holding the movable aluminum panels such as bumper as an example also crack and the Tesla technician must replace them.

Therefore, after the minor thunder bender the Tesla body shop technician must replace the brackets and the body panels instead of fixing them. And these autobody parts cost more than standard mild steel panels. In comparison when the standard car has a minor thunder bender the technician usually replaces the most damaged panel but the rest of slightly damaged panels are fixable. In Tesla’s case the technician is forced to completely replace everything. This is a one reason for relatively high cost of Tesla body work.

Another reason is the complex shape and relatively large size of these aluminum brackets holding the body panels. The Tesla brackets are large and have very sophisticated shape. Tesla uses the large brackets to hold multiple mechanical components in place including its body panels. Therefore, one bracket can hold the body panel and it can hold multiple mechanical components. Therefore to change the damaged by accident bracket the Tesla technician must remove multiple mechanical components in order to replace the bracket. Then the technician must attach the same mechanical components to the new bracket. And this adds up to the repair cost.

JW Portable Welding & Repairs welds cracked Tesla body panels and its brackets in our shop in Lucan, Ontario. Our welds not only eliminate the cracks in the panels but also increase the strength of aluminum where the bracket is attached to the panel. After welding we polish our weld in such a way that the damaged spot is not recognizable. After polishing the panel is ready for painting in the shop of your choice.

If you would like to find more about our aluminum welding please visit our aluminum trailer repairs , aluminum mobile welding service, aluminum cast mold welding, and cast aluminum welding. We also offer the very advanced welding of cracks in steel of heavy equipment including welding on cranes. Our company supports heavy equipment mechanics with our welding services.

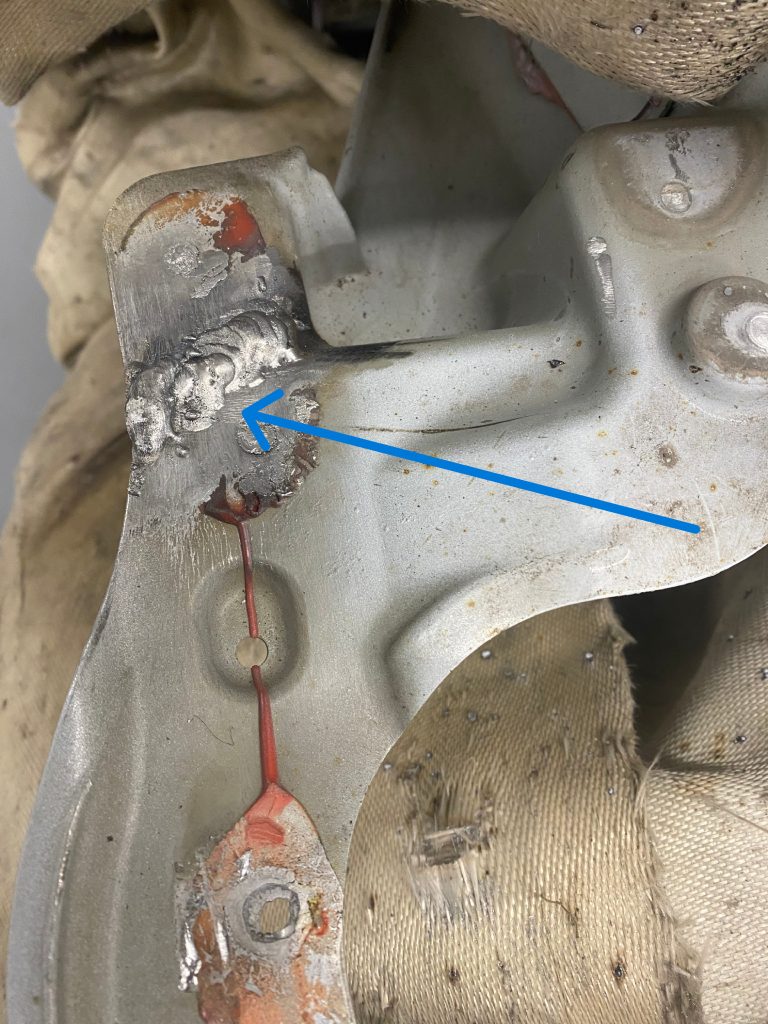

We also perform weld repairs on the aluminum Tesla’s brackets. We not only weld the cracks in these brackets but also attach back the completely separated parts. Additionally, we are able to increase the strength of the bracket and change slightly its shape. Consequently, the panels will have smaller gaps and they will be placed on stronger brackets.

Often customers do not opt to ship to us broken brackets. As mentioned above the removal of the bracket is sometimes labor intensive. Another reason for avoiding the removal of the whole bracket is the complete separation of broken off bracket’s pieces. In such case, it is better to arrange these broken pieces in correct position and we can weld them up on the car. In such case, we can come to your shop and weld in the broken bracket in place. With the repaired bracket you can continue your repair of your Tesla’s body without removing the mechanical components off the old bracket and then installing them back on a new bracket. The elimination of these activities from the repair process will alone generate very significant saving.

Welding on Tesla aluminum body is difficult. These difficulties relate to rather small thickness of the aluminum parts, complex shape of these parts and rather restrictive access to cracks. The combination of thin aluminum element and its complex shape forces the welder to weld out of position with multiple different temperature setups. Since the aluminum does not provide any overheating signals the welder often opts to use the helper to monitor the penetration on the other side of the welded material.

Additionally, the welder usually faces a very congested space surrounding the broken part. Disregarding the method we use to weld these aluminum parts we need space of about 2 feet to place our tools there and operate them comfortably. It happens rather often that we can place our tools appropriately and we can operate them fairly comfortably but the welder faces lack of visibility or very restricted visibility to the point that even mirrors do not help. Therefore sometimes we ask to remove some additional components to increase visibility for the welder.

Therefore before approaching the complex welding on aluminum Tesla body, we need to see the damages. Please send us as many images as you think is necessary to explain the situation and always place a tape measure close by on the images. We will often refer to the tape measure on the image to visualize the project