The heavy equipment repair of cracks is a complex problem that often involves complex welding and multiple modifications to minimize the impact or excessive fatigue.

Summary

In this article you will learn :

The complexity of welding cracks in heavy equipment could involve multiple welding processes and variety of consumable alloys. Additionally, it requires expensive welding equipment and very experienced welders. Therefore this highly specialized service is rather unique and is not always available locally as ordinary mechanical shops fixing your heavy equipment. JW Portable Welding offers the repair of cracks in heavy equipment in our shop in Lucan, Ontario and in your shop within mobile welding services. However, we prefer to handle larger scale projects in our shop in Lucan. The repair of cracks in heavy equipment goes hand in hand with line boring and bore welding.

You can contact us and send multiple images of your damaged heavy equipment. You can also text us on the phone number provided there. After we do an excellent job, please leave the 5 stars review of our service.

The cracks in your heavy equipment indicate a much deeper problems with solution related to:

The main goal of crack repair in heavy equipment is to restore structural integrity of the equipment along with its full functionality within the manufacturer’s tolerances. However, these modifications goal is to reduce the risk of another similar damage to the heavy equipment. These future damages could appear in the same location or other locations. As you can see, the repair of cracks in heavy equipment is not enough since without modifications the crack will appear again.

What should we use for heavy equipment repair SMAW, GMAW or GTAW? What technology is most flexible, practical and providing best results? And on the other side. What technology should we avoid in heavy equipment repair?

Without any doubt the S.M.A.W or Stick is the most useful welding technology in heavy equipment repair. In hands of experienced welder and advanced and powerful SMAW machine magic will happen. That is why SMAW dominates the market in heavy equipment repair with

When welding in difficult position the SMAW allows the welder to perform the best.

Most important advantage of SMAW for heavy equipment repair is the availability of broad selection of welding rods with advanced alloys and advanced coatings. The 60’s with 7018 welding rod are left in the past. And, now welders use advanced alloy welding rods that generate much superior welds. In fact in last 10 – 15 years the alloy rapid evolution allows to weld previously hard to fuse materials. And, do it with welds exceeding our expectations. The strength of the alloys have increased very significantly and their resistance to impact or vibration have increased too.

JW Portable Welding & Repairs considers the use of these special welding rods as a trade secret. We test these rods in shop and we remove from our use welding rods with performance exaggerated by manufacturer. However, we provide to clients tensile strengths of welding rods used in their projects.

The main weakness of SMAW is the human factor, skills of your welder is critical. The C.W.B training and certification is very useful for welding in construction industry. But, obviously welding of cracks differs significantly from their standards. T.S.S.A training seams more suitable, but thickness of material, irregularity of crack and heat factor contradict their standards. Pipefitters welding ticket would be probably more useful here than TSSA certification due to use of different weld preparations and introduction of modified welds. You need a seasoned welding professional with multiple certifications who has a strong metallurgical background and reads welds.

The welder not only should be able to follow the direction of welding technologist or welding engineer but should also be able to propose the solutions as in the below example. And, should be able to prove to the client the benefits of such solution.

Generally speaking, using Mig to weld cracks in heavy equipment repair process is a mistake. We see very often the results of Mig welding cracks in heavy farm equipment welded by farmers. We call these welds “cactus gardens”. The removal of these gardens takes very, very long. Mig is relatively easy to learn and is forgivable to the welder but not to the farm equipment.

At JW Portable Welding & Repairs, we use Mig to weld cracks in material of up to 1/4″. It means that we weld SMAW everything thicker than 1/4″.

Question is why do we have such policy?

The major and detrimental weakness of Mig for welding cracks in heavy equipment is false looking weld with low penetration. Mig welds generally look good but due to lack of penetration they are not strong. Aside of this major weakness Mig technology has also other weaknesses for heavy equipment crack welding such as

The Mig technology is a production technology and let’s leave it where it belongs

The GTAW possesses some interesting attributes heavy equipment repair process. GTAW is very precise and produces welds that resists vibration and impact, but it is very slow. The multi- position welding generates excellent quality of welds. However, it requires two hands access to the crack. This could be problematic in scarcity of space that we face. Moreover, the variety of alloys is similar to variety of consumables in Mig. Additionally, Tig heat concentrated focus becomes less concentrated when we try to weld bigger bids for thicker plates.

JW Portable Welding & Repairs uses traditional tig in repairs of small parts and components of heavy equipment.

Untraditional Tig, or a combination of Tig and Mig, seams to be very promising technology for crack welding in heavy equipment. It definitely changes the game in multiple aspects. It produces the weld with similar attributes and characteristic as Tig and it is much faster. We observe this technology and if control of welding process will improve, we will probably add this machine to our shop.

We recognize two major groups of cracks in heavy equipment: weld cracks and material cracks. As the name suggests the weld crack impacts the integrity of the weld. The weld cracks can appear on the crown, that is in the middle of the weld or on the side of the weld where it fuzzes with the base material. The location of the crack within the weld is very important since it signals completely different things.

The material cracks signal much serious matters related to destruction of component or destruction of your heavy equipment’s structure. We classify the material cracks into following groups:

Not all material cracks signal the death sentence to your equipment. Therefore when you discover the crack material please do not panic. Some material cracks in heavy equipment are not critical as they could be wall cracks or weldment cracks.

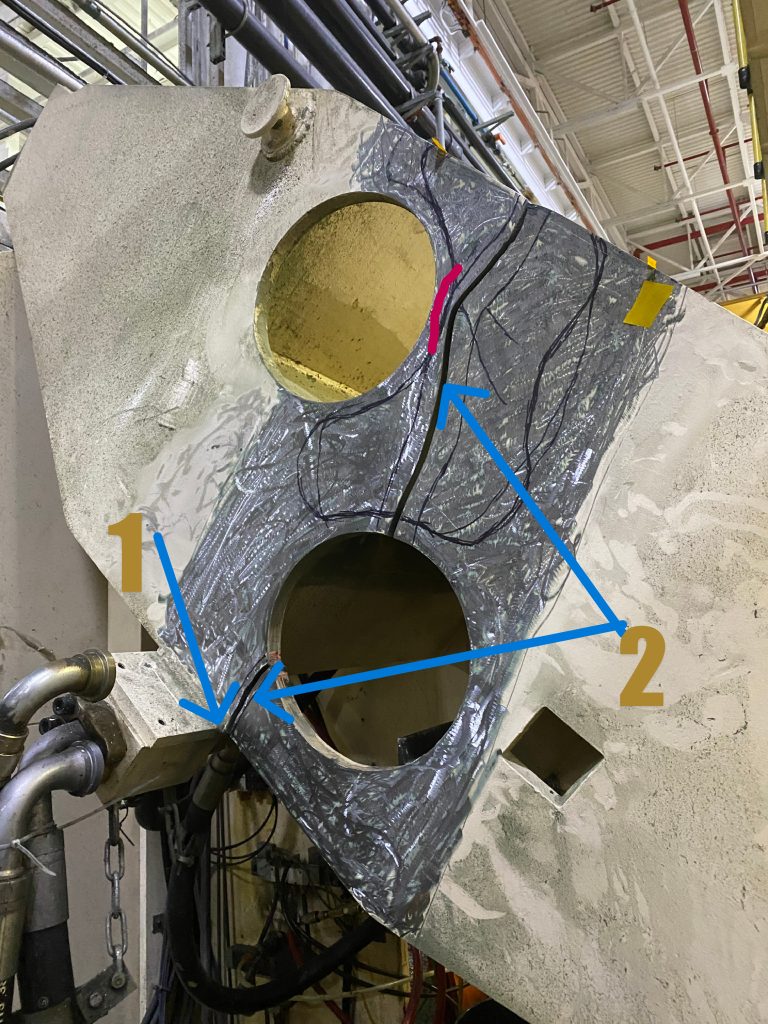

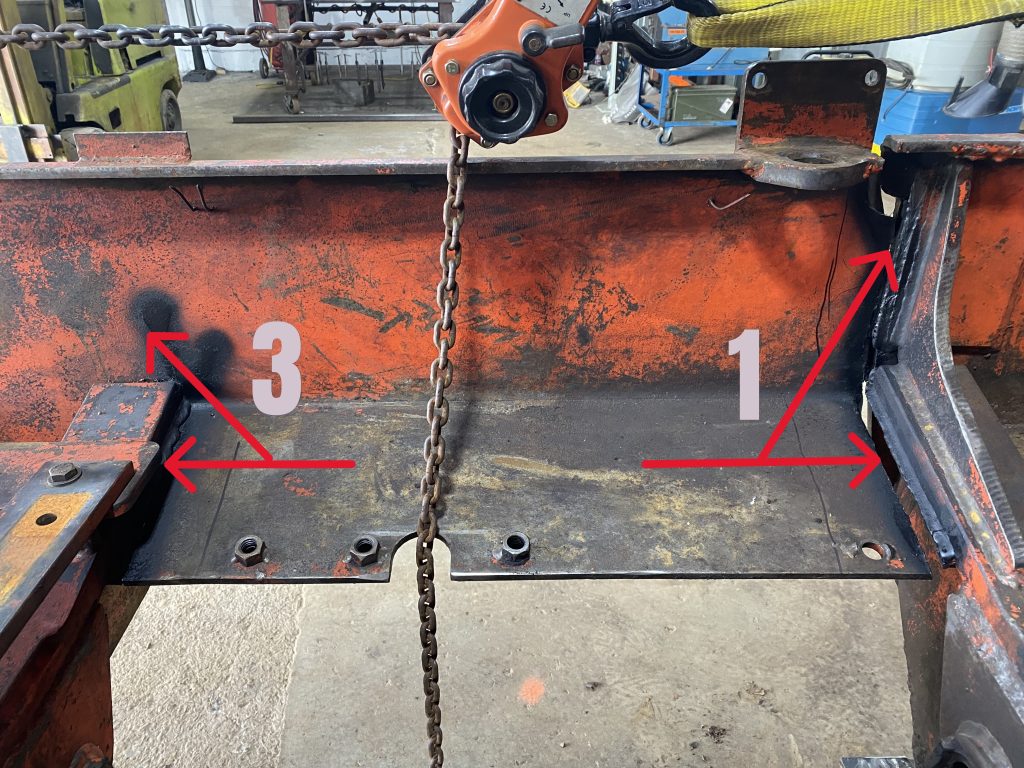

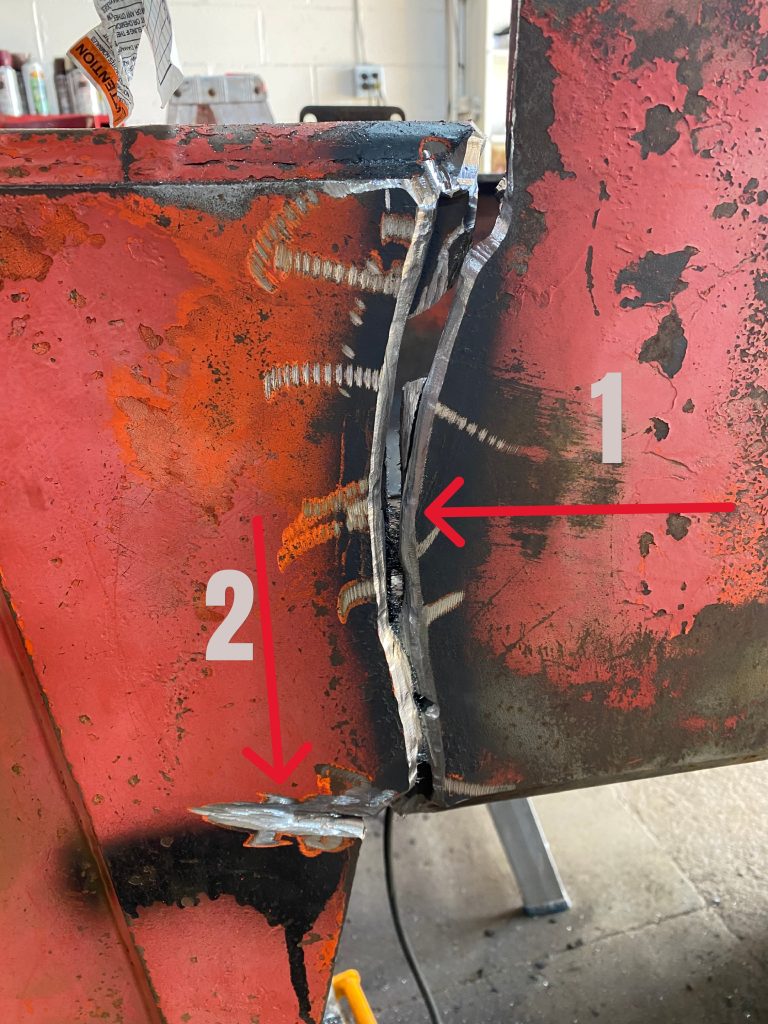

The images below show the results of malfunctioning hydraulic cylinder that has been undetected for many years by maintenance crew.

The cracked crown of the weld signifies too significant fatigue for the weld’s alloy in this size of the weld. Therefore, to correct the issue the heavy equipment’s repair of the cracked weld must involve this weld removal.

Then the JW Portable Welding & Repairs’ welder must place in this joint a bigger size weld or the same size weld but with higher tensile strength deposit.

Certainly, using the both options is also advisable. Although my suggestion is rather simple, it is not always possible. The higher tensile strength’s welding consumable could be unavailable or could not fuse well with the base material. Another issue could be the scarcity of space to place the larger weld. The larger weld could interfere with the moving parts.

JW Portable Welding & Repairs has welded on all kinds of heavy equipment and here is a glimpse of our projects.

The cracks located on the side of the weld, so called leg crack, are usually cracks of the fusion. That is why they penetrate the fusion area of the weld going under the weld. The leg cracks are often associated with material cracks under the weld. The leg cracks signify the procedure issue such as lack of preheating, colder weld, lack of proper joint preparation, or improper position. Correcting these issues is theoretically rather simple except it could become labor intensive. For example, the correcting of improper position could involve removal of many mechanical components to increase the access to the spot.

At JW Portable Welding & Repairs we tend to “fishplate” or “fish-angle” weld cracks of joints between rib and wall. We also do the same between rib and weldment.

These clean shear looking cracks usually indicate significant impact or fatigue that has acted on the joint. Therefore they require our special attention. The “fish-plating” allows us to extend the rigidness of the rib into the wall. In this way we relocate the fatigue stress to a more distant area. Additionally, the fishplate allows us to place much bigger modified weld close to the rib. The bigger weld additionally stabilizes the damaged by fatigue material. The angle-plating, on other hand, helps us to increase the strength of the whole weldment in situation of very restrictive access.

Preheating eliminates moisture from the surface of the material. And, it increases the fusion between the new weld and the old material. Therefore, preheating eliminates porosity and creates the optimal condition for a solid weld starting from the edge of the material. Since most of the cracks start from the edge of the joint, preheating eliminates the risk of cold weld in the weakest point of the joint.

Additionally, preheating provides more control to the welder since the setup of the welding machine could be on the cooler side a little. More welding control translates to better and more precise welds with less undercuts in unusual positions. It is our policy to preheat all cracks in heavy equipment prior welding disregarding the size of the crack.

Majority of original welds are traditional filet welds. The very experienced welders have positioned these filet welds in multiple planes. These experienced welders were well trained and they had a luxury of welding in comfortable position, which is rather unusual in our business. Now due to the cracks we must remove these welds and the question is what kind of weld we should place there. The question is, should we put the traditional fillet weld there if the original fillet weld has failed? Surely, we could follow the same steps of the original well trained welder, but expecting different results would be insane.

The weld cracks in older heavy equipment indicate that this equipment have worked beyond allowable tolerances. When the higher tensile strength consumable is not available and bigger size weld is impossible, we must opt for different preparation.

Therefore JW Portable Welding & Repairs always tries to improve the strength of the weld by introduction of more sophisticated preparation or creation of weldments . Definitely beveling would increase the surface of the weld. The next improvement could be a V preparation o double V preparation. In case of weld crack with a material crack these type of improvements will benefit in more stronger welds.

Surely, clients can not expect these type solutions everywhere but only in places where major cracks originate. These techniques eliminate weak spots and increase strength of welds very significantly.

Please note, the improved joint preparation could also improve the proper positioning and therefore increased penetration on the side of bevels. Considering the elimination of microcracks surrounding the main weld crack an improved joint preparation is worth the effort.

Tracing the weld cracks is relatively easy task since you follow the weld and they are clearly visible. Obviously, the metal surface must be cleaned from paint, grease and dirt. Often the difficulty arises when we try to determine the end of the weld crack. Most often the weld crack ends at the edge of material or when weld crack meets the resistance point or plane.

The crossing welds and additional plates that increase the wall thickness form resistance points or planes. It happens very often that the crack stops when meets the cross weld or much thicker material. Unfortunately, it is just a matter of time for the crack to penetrate the cross weld or go around the thicker material.

Nevertheless, the damaged weld should be removed passing the visible to the naked eye end of the crack for the distance of at least 3 x the thickness of the plate. Another way to test the end of the crack is to use MPT after groove grinding the end of the crack.

It is our policy to weld longer than 12″ large size repair welds under constant temperature. The same applies to shorter repair welds with V or double V preparation. JW Portable Welding & Repairs uses welding at constant temperature due to following reasons:

JW Portable Welding & Repairs performs all welding on fishplates and on fish-angles using constant temperature welding. Details of constant temperature welding is our trade secret.

The material cracks reduce the utilization time of your heavy equipment and sometimes they end the safe use of your equipment very abruptly. Although, their development may take years of maintenance negligence, but finally one day you discover that you can not use your heavy equipment any more due to severe malfunction.

Material cracks usually develop as a consequence of severe weld’s crown crack or with association to weld leg crack. Unless, there is an obvious engineering failure the weld crack develops first and then the material crack follows. Even in cases of high amplitude impact with low frequency that is generated by malfunctioning hydraulic cylinder the crack attacks the leg of the weld and then spreads rapidly trough the material. The material thickness of heavy equipment is often much larger than size of welds.

Material cracks could be very long and most often they completely penetrate through the material. But this does not mean that you will find the same crack directly on the opposite side. The same crack can appear other side of the plate at certain distance. Many cracks can penetrate the heavy plates angularly therefore the same crack you can find in unexpected place on other side of the plate.

These cracks could have fancy shapes with many crack branches developing from the main crack. And, then splitting once again and again. When the fatigue stress is at the medium steady level without any significant amplitude increases through the operating cycle of the working heavy equipment then the developing crack meets many points of resistance and forms structure similar to the tree.

Here are basic steps in repair of material cracks.

This procedure we have used in number of heavy equipment repairs in specials projects and welding heavy machinery.

Tracing the multiple cracks with contrast paint begins the material crack welding in your heavy equipment repair process. The tracing of cracks composes a map where these cracks are located.

Tracing exposes cracks’ length as well as their association between each other. Their dislocation severance reviles the history of damaging forces and location of resistance points or resistance zones. Every curve of the crack has the reason for its existence. By tracing the cracks you can quickly determine if structural elements are affected by cracks. If structural elements have formed resistance planes to cracks, this is a reason for smile.

However, if some structural elements are bent due to the fatigue or impact the repair of them could be impossible or very difficult and costly. It will be probably better to replace them. On other hand, cracks in castings although are very serious are sometimes reparable.

Apply the same number to crack visible on the both sides of the plate, and both sides of the weldment even if it is multi – plate or multi- component weldment. Assign one number to family of cracks forming the tree like shape.

It is very important to realize the size of the force acting on multiple walled weldment that have cracking of all weldment’s walls. Measuring the thicknesses of all cracked walls in the heavy equipment weldment provides some point of view on thickness of the fishplate. Additionally, the surface coverage of tree like crack with multiple branches indicates the fishplate size and suggest its shape. It also can point you in direction of fishplate bending.

Developing a plan to weld each crack is very important. Cracks interact with each other and therefore the order of welding repairs is very important. You should prioritize all cracks based on the order how they were formed. First priority cracks are cracks that have initiated the damage to your heavy equipment. They are usually the largest with widest gaps. Second priority take cracks that are the offsprings of first priority cracks. These smaller cracks that have appear as the result of losing structural integrity caused by the first priority crack. The third priority cracks are all small cracks that are left.

Due to existence of multiplane cracked surfaces and necessity of V or double V preparation, the welder must developed the plan not only which cracks to weld first but also which part of the crack to weld first. The exact understanding of heat distribution, warpage and position convenience should guide the welder. The welder should execute his/her plan precisely to weld all these cracks in correct order.

Plates of thickness up to 3/8″ could have V groove. Any plate thicker than 1/2″ should have double V groove with each V from both sides of the plate. However these two Vs do not have to be of the same size. The same size Vs will prohibit the warpage if the welders will oscillate between the Vs. However, if you intend to bent the material then you can change the shape of these Vs.

The width of the groove should should allow comfortable welding of groove walls but it should not be wider than 1.5 times the thickness of the plate. MPT testing of the whole crack area is highly beneficial. When beveling the crack should be kept in the middle of the bevel which is sometimes rather challenging. It is very beneficial to purchase quality abrasives for beveling since they speed up this very tiring and labor intensive process.

Alignment is crucial for bringing the heavy equipment tolerances to the original specification. Sometimes the alignment is almost effortless but sometimes it is full of struggles. After the beveling it it is a good idea to clean the sharp edges of the crack. Such cleaning will remove the small obstacles that prohibit the closing of crack’s gap.

Investing in alignment tooling and equipment will be very beneficial during aligning of cracks in heavy wall that is more than 1″ thick. It happens very often, that we are not able to check the alignment during closing the crack ‘s gap due to interference with multiple tooling. Therefore, we must check the alignment after tacking of the crack with very heavy tacks when all the alignment tooling is removed.

We have very rarely close gaps in cracks of plates that it is more than 1″ thick but we are have reduced the gap by about 95% this means that the heavy equipment needs to go through the realigning stage with certain sensors repositioning to accommodate created inaccuracy. Very often the created inaccuracy becomes negligible since the old heavy equipment operates already on the extreme tolerances and with less accuracy.

After all weld repairs are done then all weld caps are grinded off in places that you plan to place your fishplates. Also, you should use MPT to find out if there are additional cracks you have missed and if you have cracks in your welds. Any new cracks discovered must be grooved and welded and then tested with MPT.

Each numbered material crack should have a one fishplate in each plane.

Therefore, if the the same material crack spreads in horizontal plane and then transitions to vertical plane, then such crack should have two fishplates. The fishplate thickness should be such that the total thickness of cracked material and fishplate will stop the crack penetration. The fishplate’s thickness shouldn’t be thicker than the thickness of cracked material.

The edge of the fishplate should be at least of 1″ from the edge of material or from another weld. In this way, the edge or another weld will not affect the fishplate’s welds. Obviously, fishplates should not interfere with mechanical components and we should place them on flat surfaces. We should form the fishplates to follow the shape of base materials. But, then we should create slots for placing additional welds on the curves.

Also, we should create slots in large and thick fishplates should be slotted with slots welded to the base material. Please remember to cover with fishplate all cracks that are tree like shape that has been already welded.

The repair of cracks in all type of heavy equipment in any industrial sector starting from manufacturing and ending on farm equipment must make sense. The structural element such as bracing component’s crack or equipment base’s crack could be very serious. The cost of heavy equipment’s repair could be higher than the replacement cost of your heavy equipment. Same rule applies to mechanical component crack associated with bend of crucial arm. The repair of cast crack in heavy equipment depends on the type of cast and cast thickness.

If you own the older piece of equipment and you plan to use it for as long as you have own it then these cracks repair should be valued at less than 40% of the present value of your equipment.

It means simply that if you own the 10 years old heavy equipment that you can sell for $100,000 if it wouldn’t have any cracks then the repairs should not exceed 40,000. But preferably should cost about $30,000.Therefore the total cost of your 10 years old equipment would be 30,000 if your equipment is completely amortized, and you can use it for next 10 years.

If you don’t do the repairs and you sell the equipment for parts you could probably recoup about 25% of the cost, that is about $25,000. Than if you put this 25,000 towards the another old equipment that cost 100,000 you will have to add $75,000 from your pocket.

In this way, you will end up with the replacement equipment worth 100,000 and you will be in debt of 75,000 but you won’t be able to operate your heavy equipment for next 10 years. This is still 10 years old equipment and if it cracks you will have to spend another 30,000 to repair it and then you can use it for next 10 years.

Therefore you will be in debt of $105,000 when replacing the old equipment instead of being in debt for $30,000 when repair it.

Certain cracks put your heavy equipment at risk due to high cost of crack repairs, low success rate of the crack repair and high risk of low strength welds. Obviously, certain parts of heavy equipment contain higher risk of failure when cracked. They also are more costly to be repaired. These parts include structural elements such as bracing and ribbing as well as castings.

Heavy equipment ribbing provides rigidity of the whole equipment and it is built from much heavier material. Many braces between opposite walls or equipment bases are considered ribbing. In fact any element that increases the rigidity of the equipment could be called ribbing. The ribbing rigidity enforces the position of mechanical components within manufacturer’s tolerances and cracks in ribbing not only alternate the rigidity but also change the tolerances of mechanical components causing them to bend or crack. Therefore it is crucial to realize that integrity of ribbing is paramount. Welding of structural components especially if they are thick is an art by itself.

The partial cracking through ribbing should be grooved and welded in the same manner as material cracks and if the warpage will not change the position of the ribbing they should be welded with multilayer welds. However, if the crack in the ribbing causes a complete separation of part of the ribbing then the ribbing must be stabilized and its position must be confirmed with working mechanical components.

The stabilization method must maintain the ribbing position through the preheating, welding and cooling processes and mistakes made in the stabilization will cause malfunction of the equipment. Although equipment malfunction caused by welding of ribbing usually happens in manufacturing environment but it also can affect drilling rigs, lifting equipment and many others. That is why welding separation cracks of equipment structural element is rather risky and it is also expensive.

After stabilizing of ribbing and preheating the welding begins. The welder must have a plan to minimize the warpage through alternating passes and heat control. Also, some intermediate layers should be checked for cracks. Since cooling process of large welds will expose cracks it could be used to expose procedure imperfection. The joint preparation with traditional double V is successful when welder uses modified welds with alternate cooling processes. Otherwise, I recommend more sophisticated joint preparations that reduce cracking for large welds.

The welding process will be slow, frustrating and always costly therefore before committing to welding separation cracks in ribbing the welder needs to make client aware of potential risks and costs.

Cracks in casting form another group of cracks that can permanently terminate your heavy equipment. We haven’t participated in welding of cracked castings in heavy equipment in manufacturing industry. However, cracked casting is very popular in heavy equipment in earth moving industry. Heavy equipment such as excavators, loaders, bulldoggers and skidders have sometimes large casting that plays a major operational role. And, we have welded on them extensively.

A separation crack in large casting element is difficult to repair due to the thickness of the casting and issues with a consumable material used. Consumable material to weld casting could become insanely expensive for your casting and very often are not rated. Since many companies patent their welding consumables for castings, they are reluctant to publish the consumable tensile strength. Therefore, these two factors prohibit in some instances welding repair of these cracks.

Most importantly, however, many long casting elements first bend and then crack. These bends often consists of multiple microcracks forming the bend. Bended long casting elements can cause malfunction. Replacement of cracked casting element seems to be a better option, but sometimes these elements are not easily available especially for older heavy equipment.

Small cracks in casting parts of heavy equipment are relatively easy to fix. It is a good policy to take the sample of the casting and send it to the lab for testing the alloy for better consumable selection. I also advice to take the MPT of the first few passes to determine fusion.

After the welding repair activities have ended on the heavy equipment, there is a time to take action to prohibit the similar damages in the future. The major cause of heavy equipment cracks falls under one or a combination of few of following factors

The equipment owner should share the reason for heavy equipment repair with operator(s). Discussing the issue should reveal the real reasons why operator(s) abuse the equipment. Management should analize task by task why the equipment is being abuse and how to prohibit specific abusing tasks. The weekly reports/monthly reports should focus on avoidance of abusing tasks.

More frequent maintenance reports should also increase monitoring of equipment parts and areas affected by abusive actions. Aside of warning talks with the operator, the management can also take some actions to improve the situation. Installing guards, stiffeners and stoppers could improve the situation in some cases. Properly position guards will prohibit extreme movement of heavy equipment causing damages. The stiffeners reduce the size of damages and acting as a stopper they reduce extreme movements.

The operator(s) should have a clear understanding of heavy equipment capability based on manufacturing recommendations. As simple as it sounds, unfortunately, things are not as simple real world. Estimating weight of objects, proper rigging, and knowing the machine reaction plays tremendous role. The horseplaying shouldn’t be tolerated and reporting minor malfunction should be enforced. Breaking safety rules adds up into prohibited activities in the workplace. Tolerable by management negligent operation of equipment puts the responsibility for damages of heavy equipment on the management shoulders.

Lack of heavy equipment maintenance often leads to equipment breakdown and often leads to heavy cracks. Worn out pins and bushings, and out of center bores are leading cause of serous cracks in heavy construction equipment. They cause the hydraulic cylinder’s angular operation with consequences not only being extremely expensive but also tragic.

Absence of locking pins cause movement of pins during the operation and partial disengagement. The partial disengagement not only cause cracks of bores but also severe twists and bends. Loose safety pins engaging during the normal operation of heavy equipment cause the same damages as missing locking pins.

In manufacturing environment, misplaced or damaged sensors causse severe malfunction of heavy equipment and heavy cracks. Another reason for major equipment cracks in manufacturing are wearout areas affected by heavy friction.

Faulty hydraulic system causes major cracks in heavy manufacturing equipment. Nothing causes more cracks in heavy steel walls of heavy manufacturing equipment than the low vibration impact of extended and then contracted rod of main hydraulic cylinder.

At beginning the faulty operation of such system goes unnoticed then after 2-3 years the operator notice the small crack and reports it to management. Management responds usually with monitoring action. And then after another 2-3 years the whole heavy equipment breaks in half. The 1 1/2″ plate is completely penetrated by shear cut of crack that is 160 inches long and covers multiple planes. It is a disaster and a complete write-off.

The guards prohibit putting the hand on operating heavy equipment to feel the impacts caused by the hydraulic cylinder and nobody installed the vibration sensors for years to monitor the vibration of this heavy equipment. We respond to these type of cracks 2-3 times a year in Ontario. Millions of dollars are wasted due to faulty hydraulic system.

Engineering problems do happen in heavy equipment and they cause cracks. They often relate to cutting production cost by using substandard material, and substandard applications for particular solution. We call it cheap manufacturing “buy it again please”. The engineering problems are always very difficult to correct since they could affect many systems in the heavy equipment. That is why consumers should research the brands prior buying the heavy equipment. We have the policy to always report to manufacturer faulty designs of their engineering group. In this way, the manufacturer’s engineering group receives the feedback from us.